Blog Kỹ Thuật, Chăm sóc xe

DAEQUIP 3197 OPERATION MANUAL

SAFETY INFORMATION

THIS EQUIPENT IS DESIGNED BE OPERATED BY QUALIFIED PERSONNEL.IT SHOULD ONLY BE OPERATED AFTER READING THE

INSTRUCTION MANUAL AND UNDERSTANDING UNDERSTANDING THE SAFETY RULES

· WEAR SAFETY GLASSES

· DO NOT SMOKE NEAR THIS MACHINE

· USE IN A WELL VENTILATED AREA

· READ AND UNDERSTAND THE MATERIAL SAFETY DATA SHEET

· IMMEDIATELY REPAIR ANY LEAKS IN THE MACHINE OR CONNECTORS

· IMMEDIATELY CLEAN UP ANY SPILLS

· DO NOT EXCEED THE PRESSURE FOR WHICH THE MACHINE IS SET.TO

DO SO WILL CAUSE MACHINE DAMAGE, POSSIBLE PERSONAL INJURY AND VOID THE WARRANTY

1.UNCTIONING DESCRIPTION

The machine are equipped with wheels and the user can move them easily and direct himself nearby the car that need service (wasted oil-suction, new oil filling, boby-cleanning).

The functions are below explanation to use.

2. Construction name:

| 1.Tray | 2.Transparent | 3.Inlet Valve |

| 4.Oil tube | 5.Vacuum gauge | 6.Extration Probe |

| 7.Tank | 8.Wheel |

3.OPERATING PRESSURE

80~115PSI (Extraction)

14~26 PSI(Ejection)

TANK CAPACITY: 18.5 Gallons

WASTE LIQUID:ENGINE OIL

VACUUM:0~12PSI

4.PACKAGE CONTENTS

Please inspect and look for damages from shipping when package is first received.if the unit is damaged in any way, please contact customer service and include pictures if possible

In the package, you will find:

a)One 3197 Oil Extractor.

b)Probes5 pieces.

c)OPERATION MANUA 1 pieces.

- d) Tray 1 piece.

- e) Chamber 1 piece

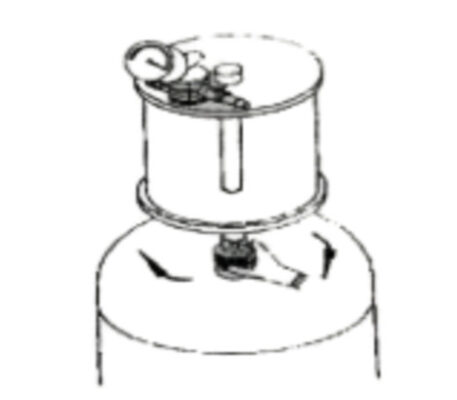

5.For the models with oil-display-transparent-tank it is necessary:

1) verify that the transparent-chamber

has not been damaged during transporting(crack);

2)mount the transparent-chamber onto

the 701. tank and check it whether

is appropriate seal;

Fig1

3)Screw up the ring-nut by hands according the i(part with screwing-up by hands).

AIR-OPERATED OIL-CHANGER EQUIPPED WITH

OIL-DISPLAY-TANK

BASIC OPERATION FOR USE OF THE OIL-CHANGER

The depression of the chamber is a basic operation which allows an easier passage of the oil from the display chamber to the tank

Fig2

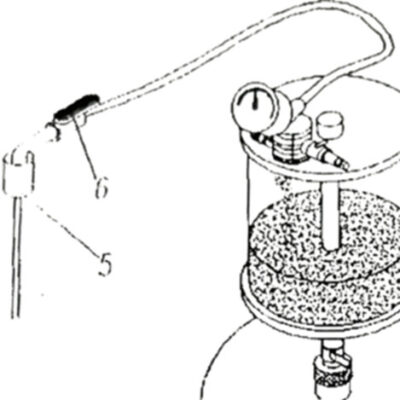

1)COMPLETE VACUUM OF THE RESERVOIR CHAMBER

-Turn off all the cocks

of the aspirator and the cock connected to the probe.

Fig3

-To connect the air-hose(8~10Bar)as position “2”, turn of the cock “3” (see fig.3) and start the depressurization of the tank up to 3/4of the scale of the vacuum-gauge “4” (fig.3) see position of the index vacuum gauge, need time 3-4min.

2)MAX VACUUM OF THE RESERVOIR

Make sure that valve “2” is turned off and set the selector “1” on “B”.Now start the value of the reservoir for max 0,8Bar which is the max value of the acale of the vacuum gauge “4” (fig.3).turn off the cock “3” and release the air-hose from pos. “2” (fig.4)

N.B. The air-filling must be made gradually.

The advantages

1)To reduce the air-consumption

2)A quicker depressurization

3)OIL-SUCTION

-Handle the cock “6” connected to the probe (fig.4) and suck the oil and fill the

reservoir(max.capacity 61.)

NOTICE:During oil-suction use the more suitable probe “5” (fig.4)

Fig4

TIME OF SUCTION WITH HOT-OIL

With probe diam.5mm.0.6l/m

With probe diam.8mm.1.6l/m

It is possible to reach a vacuum of 0.75

USE (TO WAYS)

A) To continuous compressed air connect.by this way there is a constant depression capacity of the display tank, corresponding to 0.6 bar.

B)Device in autonomy (disconnected from the compressed air). In this way with the increase of the oil volume in the display tank to values near 5L, the suction capacity (which reaches 6.5Lt and 10 Lt.)-this in order to have a constant suction up to 10L.F

Fig5

4)EMPTYING OF THE RESERVOIR AND TRANSFERING THE OIL INTO THE TANK

-When oil is discharged from the transparent bowl into the lower reservoir without opening cock 1(fig.5)It is not necessary to open the valve B only when the lower reservoir is depressurized (when there is a vauum).

Notice:repeat the above operations to complete fill of the tank

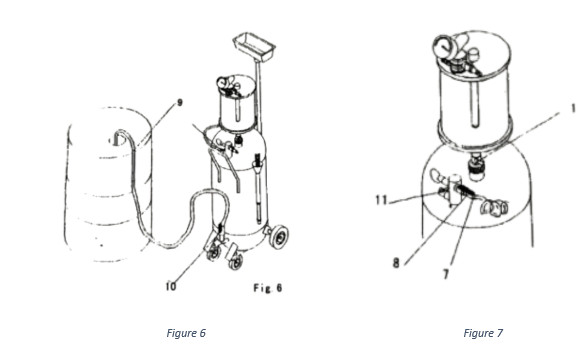

5)Operation of connecting the oil

To place the machine to the location that is need to be connected the oil, Turning off the

cock “11” before the bowl is full.(fig.6)

WARNING!!! The ball valve “1” must be closed before the tank is

added air.(Fig.6)

a).Connect the drainage-hose “9” inside a recovery-drum for exhausted oils, turn on the cock “10” in emptying position (Fig.6)

b) Connect the air hose as per pos. “7”,turn on the cock “8” (Fig.7)

c)Fill air into the tank (max 1 bar)

d) When 1 bar is reached turn off the cock “8”,if it is necessary.

e) When the emptying is finished close cock “10”。

6.SAFETY DEVICES

A safety valve will release pressure when pressure is 30PSI the ejection process.

7.ORDINARY MAINTENANCE

a) Check leakage of the machine regularly

b) Pipe to pipe connection should be close together

c) It’s necessary to release the waste oil as soon as possinle in case of the corroding of

Notice: Don’t forget to turn off the faucet when the tank is empty ank.